What Should Tge Voltage Meter Read for a 2003 Monte Carlo

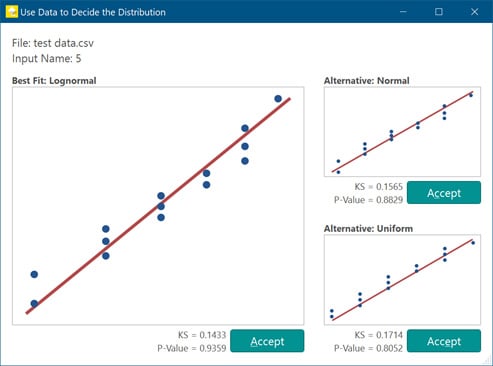

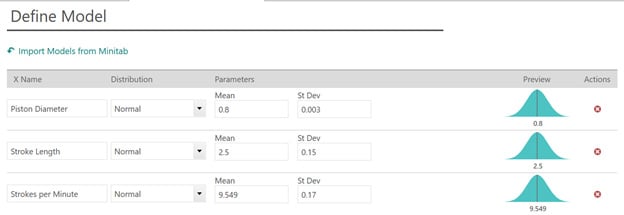

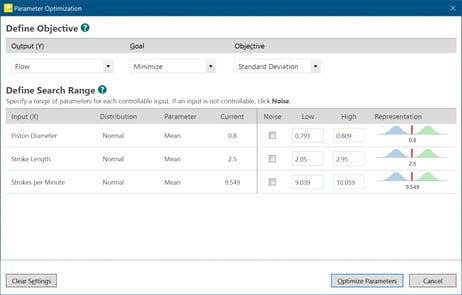

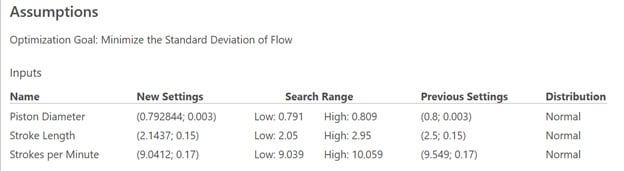

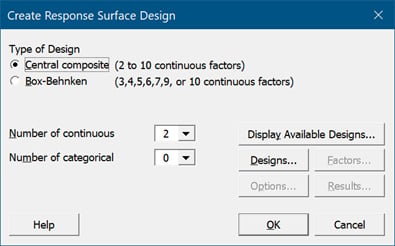

Monte Carlo simulations have come a long way since they were initially applied in the 1940s when scientists working on the atomic bomb calculated the probabilities of one fissioning uranium cantlet causing a fission reaction in another. Today we're going over how to create a Monte Carlo simulation for a known engineering formula and a DOE equation from Minitab. Since those days when uranium was in short supply and there was picayune room for experimental trial and error, Monte Carlo simulations have always specialized in computing reliable probabilities from simulated data. Today, simulated data is routinely used in many scenarios, from materials engineering science to medical device package sealing to steelmaking. It tin be used in many situations where resources are limited or gathering real data would be besides expensive or impractical. With Engage or Workspace'south Monte Carlo simulation tool, you have the ability to: Depending on the number of factors involved, simulations can be very complex. But at a basic level, all Monte Carlo simulations take 4 unproblematic steps: To create a Monte Carlo simulation, you need a quantitative model of the business activeness, plan, or process you wish to explore. The mathematical expression of your process is chosen the "transfer equation." This may be a known engineering or business formula, or information technology may exist based on a model created from a designed experiment (DOE) or regression analysis. Software similar Minitab Engage and Minitab Workspace gives you the ability to create complex equations, even those with multiple responses that may be dependent on each other. For each factor in your transfer equation, determine how its data are distributed. Some inputs may follow the normal distribution, while others follow a triangular or uniform distribution. You and then need to make up one's mind distribution parameters for each input. For example, you lot would need to specify the mean and standard departure for inputs that follow a normal distribution. If you are unsure of what distribution your information follow, Appoint and Workspace have a tool to help you lot decide. For a valid simulation, you must create a very large, random data ready for each input —something on the club of 100,000 instances. These random data points simulate the values that would be seen over a long flow for each input. While it sounds like a lot of work, this is where Appoint and Workspace smoothen. Once we submit the inputs and the model, everything hither is taken care of. With the simulated data in place, y'all can employ your transfer equation to calculate false outcomes. Running a large enough quantity of simulated input data through your model will give you a reliable indication of what the process will output over time, given the predictable variation in the inputs. A manufacturing visitor needs to evaluate the design of a proposed product: a small piston pump that must pump 12 ml of fluid per infinitesimal. You want to judge the likely performance over thousands of pumps, given natural variation in piston bore (D), stroke length (Fifty), and strokes per minute (RPM). Ideally, the pump period across thousands of pumps will take a standard deviation no greater than 0.2 ml. The starting time step in doing a Monte Carlo simulation is to determine the transfer equation. In this instance, you tin can simply use an established engineering formula that measures pump flow: Flow (in ml) = π(D/ii)2 ∗ Fifty ∗ RPM Now you must define the distribution and parameters of each input used in the transfer equation. The pump's piston diameter and stroke length are known, but y'all must calculate the strokes-per-minute (RPM) needed to attain the desired 12 ml/minute period charge per unit. Volume pumped per stroke is given by this equation: π(D/2)2 * L Given D = 0.viii and L = 2.5, each stroke displaces one.256 ml. So to reach a flow of 12 ml/infinitesimal the RPM is nine.549. Based on the functioning of other pumps your facility has manufactured, yous can say that piston bore is normally distributed with a mean of 0.viii cm and a standard difference of 0.003 cm. Stroke length is usually distributed with a hateful of 2.5 cm and a standard deviation of 0.xv cm. Finally, strokes per minute is normally distributed with a mean of 9.549 RPM and a standard deviation of 0.17 RPM. Click the Insert tab from the acme ribbon, so cull Monte Carlo Simulation. We made it easy – just give each variable a proper noun, select a distribution from the driblet-down menu and enter the parameters. Nosotros'll stick with what we described above. If you are unsure of a distribution, you can select Employ data to determine. This will prompt you to upload a .csv file of your data, and you will have a few options to choose from: The next step is to requite the equation. Here information technology'southward equally simple as giving your output a name (ours is Flow) and typing in the correct transfer equation which we identified above. You tin also add together upper and lower spec limits to see how your simulation compares. And so, in the ribbon, choose how many simulations you want to run (100,000 is a good baseline) and click the button to run the simulation. Information technology looks like this pump design exhibits also much variation and needs to be further refined before it goes into production. This is where we beginning to see the benefit of simulation. If we went right into production, we would have produced, most likely, too many rejected pumps. With Monte Carlo Simulation, nosotros are able to figure all of this out without incurring the expense of manufacturing and testing thousands of prototypes or putting it into production prematurely. Lest you wonder whether these false results hold upwardly, endeavour it yourself! Running different simulations will effect in minor variations, but the stop outcome — an unacceptable amount of variation in the menses charge per unit — volition be consistent every time. That'south the ability of the Monte Carlo method. Learning the standard difference is too high is extremely valuable, but where Engage and Workspace really stand up out is their ability to help meliorate on the situation. That's where Parameter Optimization comes in. Allow'southward look at our offset input, piston diameter. With an average of 0.8, most of our data volition autumn close to that value, or within one or two standard deviations. But what if it's more efficient to our flow for the piston to have a smaller diameter? Parameter optimization helps u.s. to reply that question. To conduct parameter optimization, we need to specify a search range for each input. For this example, for simplicity, I designated a +/- 3 standard departure range for the algorithm to search. So, either Engage or Workspace will help the states observe the optimal settings for each input to reach or goal, which in this instance is to reduce the standard departure. Selecting the advisable range is important; make sure that the total range you input is feasible to run; information technology does no good to discover an optimal solution that isn't possible to replicate in production. If you've used the Response Optimizer in Minitab Statistical Software, the idea is like. Hither are our results: Based on this, if we want to reduce our standard difference, we should reduce our Stroke Length and our Strokes per Infinitesimal. Our piston diameter can stay in a like place. And remember the primal to Monte Carlo simulation – we are able to find all of this out without building and single new prototype or conducting a new experiment. What if y'all don't know what equation to employ, or y'all are trying to simulate the outcome of a unique process? This is where we can combine the designed experiment capabilities of Minitab Statistical Software with the simulation capabilities of Engage or Workspace. An electronics manufacturer has assigned you to improve its electrocleaning performance, which prepares metallic parts for electroplating. Electroplating lets manufacturers coat raw materials with a layer of a different metal to accomplish desired characteristics. Plating will not adhere to a dirty surface, and so the company has a continuous-flow electrocleaning system that connects to an automatic electroplating auto. A conveyer dips each part into a bath which sends voltage through the role, cleaning it. Inadequate cleaning results in a loftier Root Mean Square Average Roughness value, or RMS, and poor surface finish. Properly cleaned parts take a smooth surface and a low RMS. To optimize the process, you can adjust ii critical inputs: voltage (Vdc) and current density (ASF). For your electrocleaning method, the typical engineering science limits for Vdc are 3 to 12 volts. Limits for current density are 10 to 150 amps per square foot (ASF). Yous cannot employ an established textbook formula for this procedure, but you can set upwardly a Response Surface DOE in Minitab to determine the transfer equation. Response surface DOEs are often used to optimize the response by finding the all-time settings for a "vital few" controllable factors. In this case, the response will be the surface quality of parts after they take been cleaned. To create a response surface experiment in Minitab, choose Stat > DOE > Response Surface > Create Response Surface Design. Because nosotros have two factors—voltage (Vdc) and current density (ASF)—nosotros'll select a two-gene central blended design, which has xiii runs. Afterwards Minitab creates your designed experiment, you need to perform your thirteen experimental runs, collect the data, and tape the surface roughness of the 13 finished parts. Minitab makes information technology easy to clarify the DOE results, reduce the model, and check assumptions using residual plots. Using the concluding model and Minitab's response optimizer, you can find the optimum settings for your variables. In this case, y'all set up volts to seven.74 and ASF to 77.8 to obtain a roughness value of 39.four. The response surface DOE yields the post-obit transfer equation for the Monte Carlo simulation: Roughness = 957.eight − 189.four(Vdc) − iv.81(ASF) + 12.26(Vdc2) + 0.0309(ASF2) Now you lot can set the parametric definitions for your Monte Carlo Simulation inputs and bring them over to Engage or Workspace. Note that the standard deviations must exist known or estimated based on existing process cognition. This is truthful for all Monte Carlo inputs. Volts are normally distributed with a hateful of vii.74 Vdc and a standard departure of 0.14 Vdc. Amps per Square Foot (ASF) are normally distributed with a mean of 77.8 ASF and a standard divergence of 3 ASF. This works exactly the aforementioned as Step iii. Click Insert > Monte Carlo Simulation from the ribbon, add together your inputs and ascertain their parameters, and then enter your model. In this example, if you have the latest version of Minitab you can right-click and hit Send to Appoint or Send to Minitab Workspace. If non, you can manually copy it over from the Minitab output and paste it into the model field in Engage or Workspace. The summary shows that even though the underlying inputs were normally distributed, the distribution of the RMS roughness is non-normal. The summary as well shows that the transmitted variation of all components results in a standard difference of 0.521, and process knowledge indicates this is a good procedure event. Based on a DOE with just thirteen runs, nosotros can determine the reality of what will be seen in the process. Again, since this is based on simulated information, your answers will be slightly different, but the general answers should exist correct. If necessary, we tin await at parameter optimization to tweak our answers and find an optimal solution. This article is based on a presentation delivered by Paul Sheehy, Minitab technical grooming specialist, at the ASQ Lean Vi Sigma Conference in Feb 2012.

The iv Steps to Get Started for Whatever Monte Carlo Simulation

i. Identify the Transfer Equation

2. Ascertain the Input Parameters

3. Fix Simulation

four. Analyze Process Output

The 4 Steps for Monte Carlo Using a Known Engineering science Formula

1. Identify the Transfer Equation

2. Define the Input Parameters

3. Fix the Simulation in Engage or Workspace

4. Simulate and Clarify Process Output

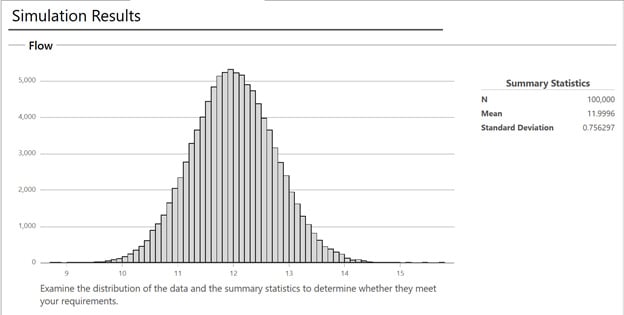

For the random data generated to write this article, the mean flow charge per unit is 11.996 based on 100,000 samples. On average, we are on target, but the smallest value was viii.7817 and the largest was 15.7057. That's quite a range. The transmitted variation (of all components) results in a standard deviation of 0.756 ml, far exceeding the 0.2 ml target.

For the random data generated to write this article, the mean flow charge per unit is 11.996 based on 100,000 samples. On average, we are on target, but the smallest value was viii.7817 and the largest was 15.7057. That's quite a range. The transmitted variation (of all components) results in a standard deviation of 0.756 ml, far exceeding the 0.2 ml target.

1 More Optional Stride: Parameter Optimization

Monte Carlo Using a Design of Experiments (DOE) Response Equation

one. Identify the Transfer Equation

ii. Define the Input Parameters

three. Gear up upwards the Simulation in Appoint or Workspace

4. Simulate and Analyze Procedure Output

Source: https://blog.minitab.com/en/the-4-simple-steps-for-creating-a-monte-carlo-simulation-with-engage-or-workspace

Belum ada Komentar untuk "What Should Tge Voltage Meter Read for a 2003 Monte Carlo"

Posting Komentar